Kaizen as you might know means “Continuous Improvement” in Japanese. It’s a mindset and action of taking small incremental changes for the better. This has helped us grow into the business you see before you, over the past 7 years. We’re never

Kaizen as you might know means “Continuous Improvement” in Japanese. It’s a mindset and action of taking small incremental changes for the better. This has helped us grow into the business you see before you, over the past 7 years. We’re never

ones to stand still and as a print company, are always pushing for better quality and service across our entire business. This includes our print finishing team. In the past few months we’ve installed our third laminator, the Matrix Duo 370 and what a beauty she is.

We realise while many of our customers are aware of the term “lamination”, they may not really know what happens in the laminating process and so here is our little guide. If you’re unsure about anything below, do get in touch or leave a message. We’d be only too happy to assist.

What is lamination in printing?

Lamination is the print finishing process of using pressure and / or heat to bind paper or card to a thin plastic film called laminate. This laminate protects the paper and can ensures durability over time.

Almost every product we supply has the ability to be laminated and there are many pro’s as to why this would be beneficial to your print project. In fact, other than additional cost, there’s not really any downside to laminating your print.

Lamination protects your print

The primary benefit of any lamination on your printing is that it adds an additional layer of protection between the paper and the elements. When printing restaurant menus for example, it’s always recommended to use a laminate to protect the menu from greasy hands, accidental spills from drinks and sauces. We offer multiple weights of laminate including an Ultra Heavy version that while not completely indestructible, it’s pretty close. Menus aren’t the only product that benefit from lamination, posters, flyers and roller banners all have the potential of accidental damage and lamination can also save the day in many instances.

Lamination eliminates cracking on printed paper

Heavy ink coverage and creasing can cause cracking in the paper and while this is relatively uncommon, in instances where it presents itself, laminating the cover can completely rectify this issue by providing the additional support the paper needs when be creased and folded or made into a booklet.

Lamination can enhance colour on your prints

The rule with lamination is that gloss can brighten up your print whereas matt lamination will mute the colours slightly. Whether one or the other is better is purely subjective but as a business we recommend the matt over gloss 9 out of 10 times. In our opinion it’s nicer, but you are free to disagree.

Alternatives to Lamination – Spot UV

Spot UV (ultra violet) is a Varnish added to “highlight” areas on a printed project. Used in some very bespoke designs it can accentuate logos, images or create feature overlays to your printing. Spot UV comes in gloss, matt and some very funky glitter options. At present we offer Spot UV on our Luxury Business Card Range.

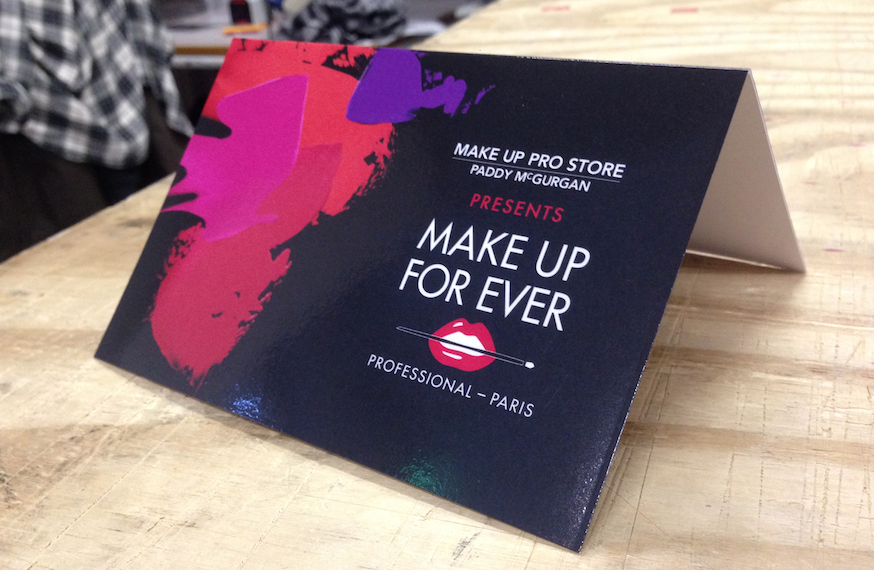

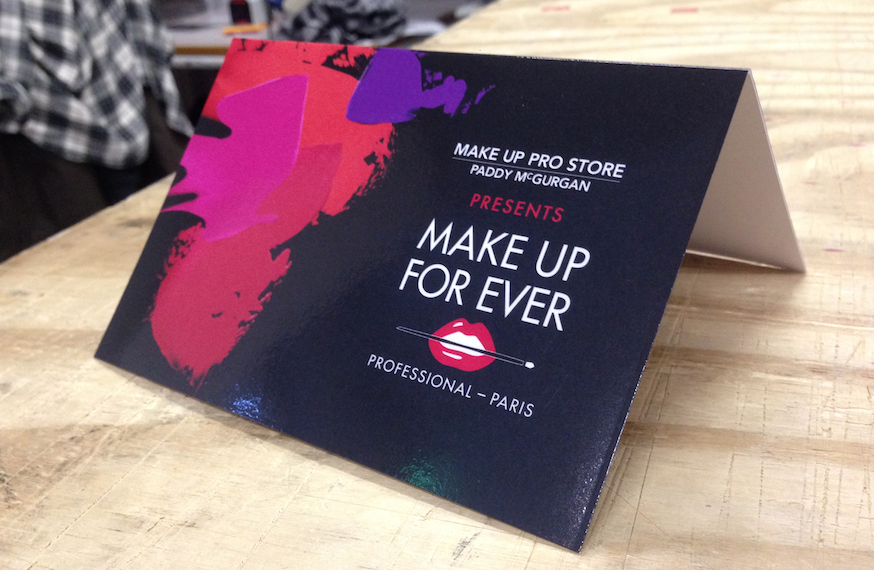

Gloss Lamination Example

Above you’ll see a great example of a gloss lamination on a gift voucher for Paddy McGurgan’s Make Up Pro store here in Belfast. The vibrancy of the colour is really set off by the gloss and the already striking colour palette is strengthened by the finish.